Features and scope of application:

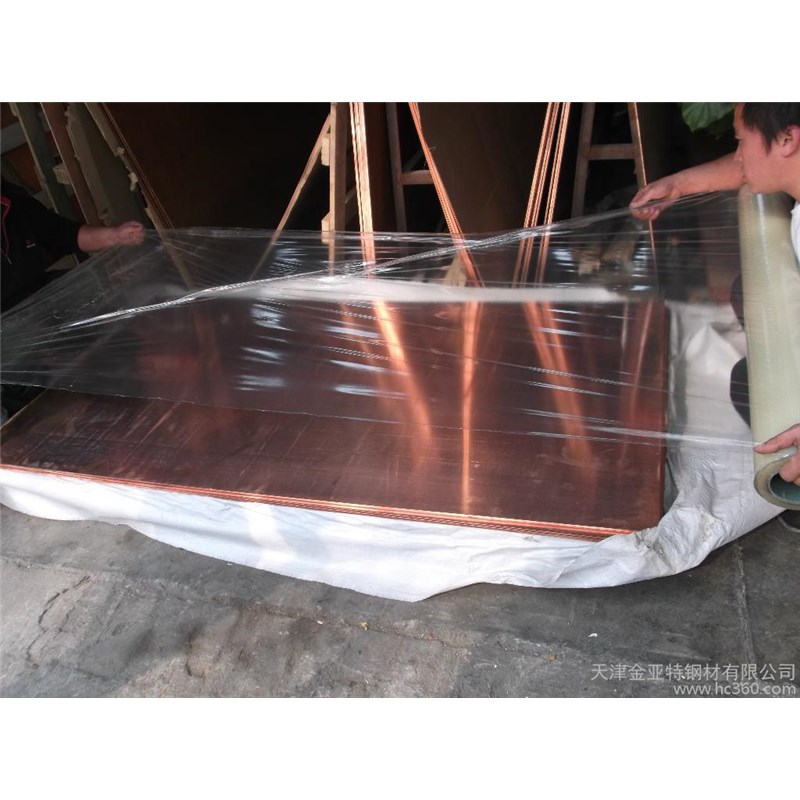

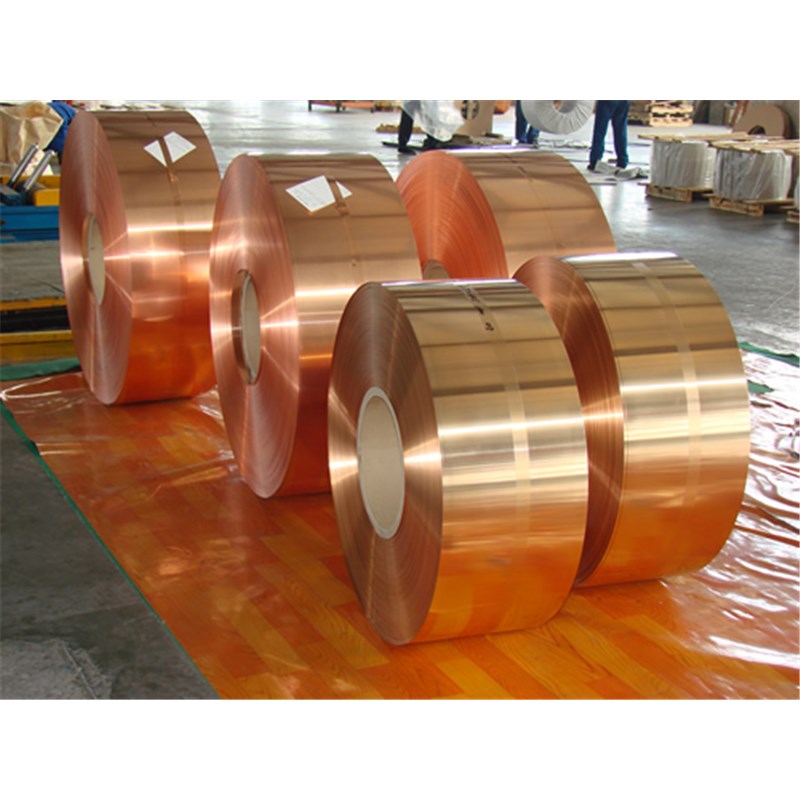

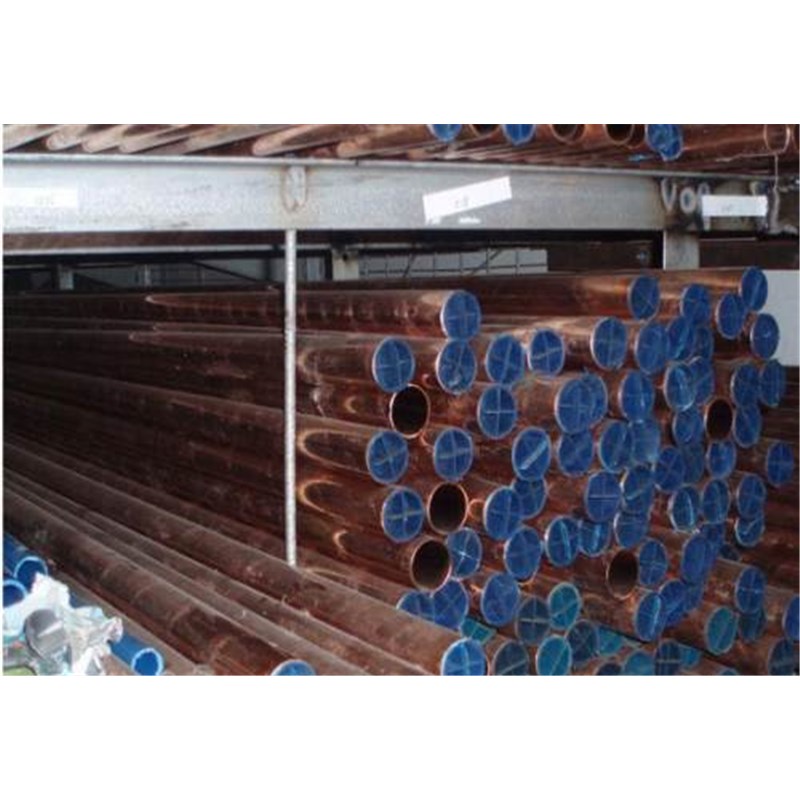

TP2 phosphorus deoxidized copper has good welding performance and cold bending performance. Generally, it has no tendency of 'hydrogen disease'. It can be processed and used in a reducing atmosphere, but it is not suitable for processing and use in an oxidizing atmosphere. TP1 has less residual phosphorus than TP2, so its conductivity and thermal conductivity are higher than TP2. TP1 and TP2 are mainly used for pipe applications, and can also be supplied by plates, belts or rods and wires. Used as gasoline or gas delivery pipe, drain pipe, condensing pipe, mine pipe, condenser, evaporator, heat exchanger, train box parts.

TP2 phosphorus deoxidized copper

chemical composition:

Copper + silver Cu + Ag: ≥ 99.85

Tin Sn: ≤0.01

Lead Pb: ≤0.005

Phosphorus P: 0.013 ~ 0.050

Nickel Ni: ≤0.01

Iron Fe: ≤ 0.05 (0.005)

锑 Sb : ≤ 0.002

Sulfur S : ≤ 0.005

Arsenic As : ≤0.005

铋 Bi: ≤ 0.002

Oxygen O: ≤0.01

Note: ≤0.15 (impurities)

Mechanical properties:

Tensile strength σb (MPa): 215~275

Elongation δ10 (%): ≥25

Hardness: 55~100HV

Note: Tensile mechanical properties at room temperature

Sample size: thickness ≥ 0.3

Status: Phosphorus deoxidized copper strip (1/4 hard, ≥0.3mm) copper